**The views and results in the following White Paper are the property of Beyers Analytical and do not necessarily reflect the opinions of Kombucha Brewers International.**

Introduction

Beyers Analytical Brewing Sciences, LLC (BABS) is an analytical laboratory based in Fort Collins, Colorado that is dedicated to performing chemical and microbiological measurements for kombucha, beer, spirits, wine, and coffee producers. The analysts at BABS are certified beer chemists with the Alcohol and Tobacco Tax and Trade Bureau (TTB) and are qualified to provide accurate measurements of components within beverage products. BABS provides education for kombucha producers regarding analytical techniques that can be used to monitor their products. We are often asked what methods can be used to monitor ethanol in kombucha.

The low level of ethanol required for non-alcoholic kombucha necessitates quick, affordable, and reliable testing that can be used to measure levels at or below 0.5% alcohol by volume (ABV). This study presents a comparison of four ethanol measurement technologies for the kombucha industry. Eight off-the-shelf kombucha products were analyzed in a blind test for ethanol content using gas chromatography (GC), an OptiEnz Sensors ethanol sensing system, an Anton-Paar Alcolyzer, and distillation paired with an Anton-Paar densitometer.

Results and Discussion

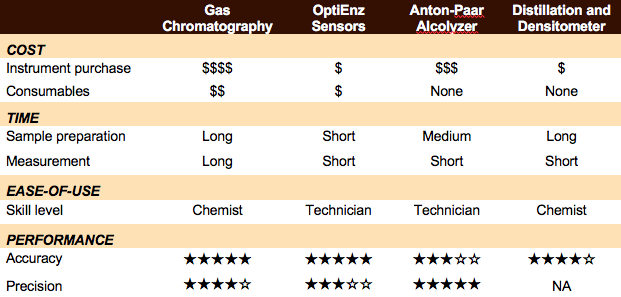

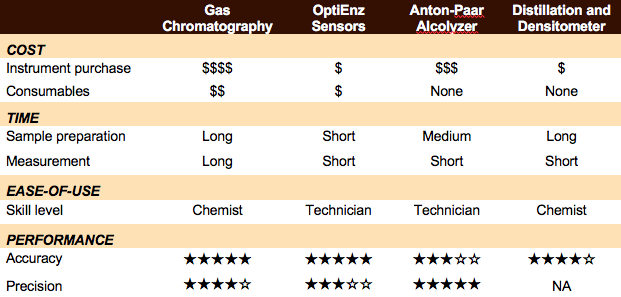

The table below presents the advantages and disadvantages of each ethanol measurement technology. These items are worth considering prior to using commercial laboratory testing or purchasing an instrument as part of a quality control program.

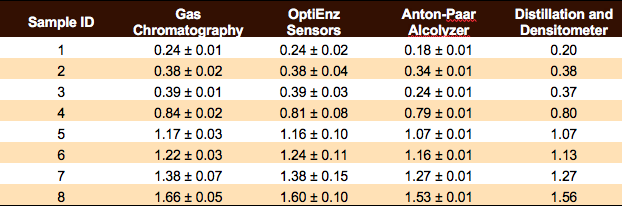

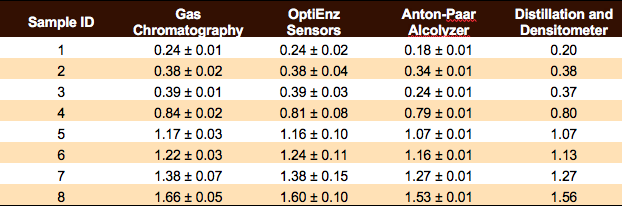

Average ethanol measurements for each kombucha sample and performance statistics for each technology are presented in the table below.

Gas Chromatography

Measurements of ethanol concentration made using GC were taken to be the target concentration for calculations of accuracy in this study due to the technology’s widespread use as a “gold standard.” However, high upfront costs, high maintenance costs, complicated procedures, and long measurement times prevent most kombucha producers from using this technology at their facilities.

OptiEnz Sensors Ethanol Sensing System

The OptiEnz Sensors ethanol sensing system is more affordable than GC and the Anton-Paar. Alcolyzer, is easier to use than GC, and has one of the shortest measurement times of these technologies. This technology provided ethanol measurements in kombucha that most closely matched GC measurements.

Anton-Paar Alcolyzer

The Anton-Paar Alcolyzer is the easiest technology to use, provides short measurement times, and is more affordable than GC. Ethanol measurements made with this technology were precise, but consistently lower than GC measurements.

Distillation and Anton-Paar Densitometer

Distillation has a low upfront cost, very long sample preparation times, and requires higher-level technical training. Ethanol measurements made with this technology were consistently lower than GC measurements.

Conclusions

All the tested technologies are capable of measuring ethanol at concentrations found in kombucha, but the advantages and disadvantages of each method need to be considered when implementing a testing program. Proximity to the threshold concentration of 0.5% is also an important consideration. Any instrument is only as good as the operator running it. Training, accurate standards, and quality control are required to achieve reliable measurements.

Experimental Procedures

Gas Chromatography

Headspace gas chromatography – flame ionization detection (HS/GC-FID) measurements and sample preparation were performed using AOAC methods for determination of ethanol in kombucha (AOAC 2016.12). Analysis was completed on a HP 5890 Series II gas chromatograph (four measurements per sample) with a Restek Stabilwax-DA capillary column using nitrogen as the carrier gas, and resolution of methanol, ethanol, isopropanol, 1-propanol, and acetone was possible using this setup. A calibration curve was constructed using Cerilliant ethanol standards purchased from Sigma-Aldrich.

Headspace gas chromatography – flame ionization detection (HS/GC-FID) measurements and sample preparation were performed using AOAC methods for determination of ethanol in kombucha (AOAC 2016.12). Analysis was completed on a HP 5890 Series II gas chromatograph (four measurements per sample) with a Restek Stabilwax-DA capillary column using nitrogen as the carrier gas, and resolution of methanol, ethanol, isopropanol, 1-propanol, and acetone was possible using this setup. A calibration curve was constructed using Cerilliant ethanol standards purchased from Sigma-Aldrich.

OptiEnz Sensors Ethanol Sensing System

Ethanol measurements were performed using an OptiEnz Sensors ethanol sensing system. The instrument was calibrated over 10 minutes using prepared ethanol standards. Ethanol measurements (six measurements per sample) were made by diluting 0.1 mL of sample into 50 mL of buffer, immersing the sensor probe into the dilute solution and allowing the system to stabilize for three minutes.

Ethanol measurements were performed using an OptiEnz Sensors ethanol sensing system. The instrument was calibrated over 10 minutes using prepared ethanol standards. Ethanol measurements (six measurements per sample) were made by diluting 0.1 mL of sample into 50 mL of buffer, immersing the sensor probe into the dilute solution and allowing the system to stabilize for three minutes.

Anton-Paar Alcolyzer

Density and Alcolyzer measurements were performed using an Anton-Paar DMA 4500 M-EC with Enhanced Calibration for Ethanol paired with an Alcolyzer Beer ME module and Sample Handling Unit (Xsample 22). The instrument was calibrated with degassed, deionized water and achieved a density measurement of 0.99820 ± 0.00001 g/mL at 20ºC. Sample analysis (six measurements per sample) was performed by pumping 40 mL of sample through the system, bringing the sample temperature to 20.00 ± 0.01°C, and then collecting density and Alcolyzer measurements.

Density and Alcolyzer measurements were performed using an Anton-Paar DMA 4500 M-EC with Enhanced Calibration for Ethanol paired with an Alcolyzer Beer ME module and Sample Handling Unit (Xsample 22). The instrument was calibrated with degassed, deionized water and achieved a density measurement of 0.99820 ± 0.00001 g/mL at 20ºC. Sample analysis (six measurements per sample) was performed by pumping 40 mL of sample through the system, bringing the sample temperature to 20.00 ± 0.01°C, and then collecting density and Alcolyzer measurements.

Distillation and Anton-Paar Densitometer

Kombucha samples (100 mL per sample) were distilled according to the TTB-recommended distillation-specific gravity method (AOAC 935.21). Density measurements (one measurement per sample) were made using the Anton-Paar densitometer.

Kombucha samples (100 mL per sample) were distilled according to the TTB-recommended distillation-specific gravity method (AOAC 935.21). Density measurements (one measurement per sample) were made using the Anton-Paar densitometer.

Headspace gas chromatography – flame ionization detection (HS/GC-FID) measurements and sample preparation were performed using AOAC methods for determination of ethanol in kombucha (AOAC 2016.12). Analysis was completed on a HP 5890 Series II gas chromatograph (four measurements per sample) with a Restek Stabilwax-DA capillary column using nitrogen as the carrier gas, and resolution of methanol, ethanol, isopropanol, 1-propanol, and acetone was possible using this setup. A calibration curve was constructed using Cerilliant ethanol standards purchased from Sigma-Aldrich.

Headspace gas chromatography – flame ionization detection (HS/GC-FID) measurements and sample preparation were performed using AOAC methods for determination of ethanol in kombucha (AOAC 2016.12). Analysis was completed on a HP 5890 Series II gas chromatograph (four measurements per sample) with a Restek Stabilwax-DA capillary column using nitrogen as the carrier gas, and resolution of methanol, ethanol, isopropanol, 1-propanol, and acetone was possible using this setup. A calibration curve was constructed using Cerilliant ethanol standards purchased from Sigma-Aldrich. Ethanol measurements were performed using an OptiEnz Sensors ethanol sensing system. The instrument was calibrated over 10 minutes using prepared ethanol standards. Ethanol measurements (six measurements per sample) were made by diluting 0.1 mL of sample into 50 mL of buffer, immersing the sensor probe into the dilute solution and allowing the system to stabilize for three minutes.

Ethanol measurements were performed using an OptiEnz Sensors ethanol sensing system. The instrument was calibrated over 10 minutes using prepared ethanol standards. Ethanol measurements (six measurements per sample) were made by diluting 0.1 mL of sample into 50 mL of buffer, immersing the sensor probe into the dilute solution and allowing the system to stabilize for three minutes. Density and Alcolyzer measurements were performed using an Anton-Paar DMA 4500 M-EC with Enhanced Calibration for Ethanol paired with an Alcolyzer Beer ME module and Sample Handling Unit (Xsample 22). The instrument was calibrated with degassed, deionized water and achieved a density measurement of 0.99820 ± 0.00001 g/mL at 20ºC. Sample analysis (six measurements per sample) was performed by pumping 40 mL of sample through the system, bringing the sample temperature to 20.00 ± 0.01°C, and then collecting density and Alcolyzer measurements.

Density and Alcolyzer measurements were performed using an Anton-Paar DMA 4500 M-EC with Enhanced Calibration for Ethanol paired with an Alcolyzer Beer ME module and Sample Handling Unit (Xsample 22). The instrument was calibrated with degassed, deionized water and achieved a density measurement of 0.99820 ± 0.00001 g/mL at 20ºC. Sample analysis (six measurements per sample) was performed by pumping 40 mL of sample through the system, bringing the sample temperature to 20.00 ± 0.01°C, and then collecting density and Alcolyzer measurements. Kombucha samples (100 mL per sample) were distilled according to the TTB-recommended distillation-specific gravity method (AOAC 935.21). Density measurements (one measurement per sample) were made using the Anton-Paar densitometer.

Kombucha samples (100 mL per sample) were distilled according to the TTB-recommended distillation-specific gravity method (AOAC 935.21). Density measurements (one measurement per sample) were made using the Anton-Paar densitometer.